- Home Page

- Company Profile

-

Our Products

- Fire Suppression Systems

- FK 5112 Suppression System

- Clean Agent Cylinderless System

- Clean Agent Cylinderless System for Car

- Wind Turbine Fire Detection and Suppression System

- Vehicle Fire Protection System

- Mild Steel Novec 1230 Fire Suppression System

- Fire Extinguishing System For Electrical Cabinets

- Aerosol Fire Suppression System

- Novec 1230 Flooding System

- Hfc 227ea Based Fire Suppression System

- Modular Clean Agent HFC236fa Extinguishers

- Aerosol Based Fire Suppression System

- FM200 Fire Suppression System

- Cylinder Less Tube Based Fire Detection Suppression Systems

- High Voltage Transformer Fire Suppression System

- Hfc227ea Clean Agent Fire Extinguishers

- Novec 1230 Clean Agent Suppression Systems

- Carbon Steel Fm 200 Fire Suppression System

- Direct Tube Based Fire Suppression System

- Novac 1230 Fire Flooding Systems

- Clean Agent Fire Suppression System

- Hfc 227ea Auto Fire Extinguishing System

- Car Fire Protection System

- Fire Suppression For Power Generators

- Hfc227ea Total Flooding System

- Dual Agent Retardant fire Suppression System

- Heat Sensing Tube

- Clean Agent Fire Suppression System for Wind Turbine

- Bus Engine Fire Protection System

- Fire Trace System

- Novec 1230 Fire Suppression System

- SEVO Tubing Suppression System

- Fire Detection And Fire Suppression System

- Heavy Vehicle Fire Suppression Systems

- Fire Sprinkler System Installation Service

- Vehicle Fire Suppression System

- Pre Engineered Fire Suppression System

- Server Rack Fire Suppression System

- Mild Steel Fire Suppression Systems

- Fire Suppression System (Capacitor Panel)

- Electrical Panel Detection Suppression System

- Fire Detection Tube Suppression System

- Fire Extinguishing System For Electrical Panel

- Electrical Panel Gas Suppression System

- Novec 1230 Fire Suppression System for Industrial

- Fm200 Gas Based Fire Suppression Systems

- FM200 Gas Based Fire Suppression Systems For Wind Turbines

- Tube Based Fire Suppression System

- Novec 1230 Fire Gas Suppression System For Electrical Panel

- Novec 1230 Fire Extinguishing System

- Novec 1230 Gas Suppression System For Wind Turbine Fire Suppression System

- Nitrogen Injection Transformer Fire Protection System

- Electrical Panel Fire Suppression System

- Dual Agent Retardant Fire Suppression System

- Diffusible FE36 Fire Suppression System

- Hazardous Cabinets Fire Suppression System

- Chemical Fire Suppression Systems

- Nitrogen NITFP System

- Automatic Fire Detection and Suppression System

- Novec 1230 Fire Suppression Systems

- Fire Suppression For Wind Turbines

- Bladder Tank Proportioning System

- Electrical Panel Fire Suppression

- Fk 5112 Fire Suppression System

- Fire Extinguishing Systems

- Fire Alarms And Detection Systems

- White Addressable Duct Detector

- UV IR Flame Detector

- Agni Sounder Hooter

- Addressable Fire Alarm System

- Fire Alarm System Amc Service

- Conventional Fire Alarm System

- Digital Addressable Fire Alarm System

- Aspirating Systems Smoke Detectors

- Agni Addressable Security Fire Alarm

- Fire Detection And Fire Alarm System

- Uv Ir Flame Detector System

- Ravel 2 zone Conventional Fire Alarm System

- Addressable Photoelectric Duct Detector

- Fire Alarm Sounder

- Fire Response Indicator

- Vesda Aspirating Smoke Detection System

- 4 Zone Addressable Fire Alarm System

- Ravel 4 zone Conventional Fire Alarm System

- Fire Detection Fire Alarm System

- Co2 Flooding/Suppression System

- High Pressure Co2 Automatic Fire Extinguishing System

- Co2 Gas Fire Suppression System

- CO2 Suppression System

- CO2 Fire Flooding

- ELECTRICAL PANEL CO2 FLOODING SYSTEM

- Automatic Pipeline Co2 Fire Suppression System

- Co2 Fire Flooding System

- Co2 Cylinder Fire Suppression System

- In Direct CO2 Flooding System

- Co2 Based Fire Suppression Systems

- Automatic Co2 Flooding System

- Automatic CO2 Flooding System

- Gas Based Co2 Flooding System

- Automatic Pipeline CO2 Fire Suppression System

- Co2 Fire Suppression System

- Passive Fire Protection

- Fire Extinguishers

- Twin Trolley Type Fire Extinguisher

- Co2 Fire Extinguisher Refilling Service

- Clean Agent Type Fire Extinguisher

- Amc For Fire Fighting System

- Co2 type fire Extinguisher

- Mild Steel Wet Chemical Fire Extinguisher

- Carbon Steel Abc Fire Extinguisher

- Automatic Ceiling Mounted D Type Fire Extinguisher

- Water Spray Sprinkler Systems

- Kanex Fire Extinguishers

- Fe36 Clean Agent Fire Extinguisher

- Modular Dry Chemical Powder Extinguishers

- Kitchen Fire Suppression System

- Kitchen Fire Suppression System

- Mild Steel Kitchen Fire Suppression

- Kitchen Hood Fire Suppression System

- Automatic Kitchen Fire Extinguishing System

- Kitchen Fire Extinguisher

- kitchen Nozzle Fire Suppression System

- Restaurant Kitchen Fire Suppression System

- Fire Suppression System For Commercial Kitchen

- Commercial Kitchen Fire Suppression System

- HW & MV Fire Protection System

- Commercial Gas Leak Detector

- Medium Velocity Water Spray System (MVWS)

- Transformer Fire Protection System

- Transformer Fire Prevention System

- Transformer Fire Suppression Systems

- Conveyor belt system fire protection system

- Nitrogen Injection Fire Protection System For Transformer

- High Velocity Water Spray System (HVWS)

- Fire Suppression Accessories

- Fire Hydrant System

- Clean Agent Gas Refilling

- Fire Fighting Foams

- Smoke Detector

- Ravel Beam Smoke Detector

- Addressable Photoelectric Smoke Detector

- Addressable Smoke Detector

- Fire Alarm Addressable Smoke Detector

- Battery Addressable Smoke Detector

- Polycarbonate Smoke Detector

- Agni Smoke Detector

- Conventional Optical Smoke Detectors

- Addressable Duct Smoke Detector

- Agni Wireless Smoke Detector

- White Polycarbonate Smoke Detector

- Manual Call Point

- Fire Retardant Fabric

- Fire Alarm Control Panel

- Heat Detector

- Beam Detectors

- Fire Door

- HW&MV Fire Protection

- Fire Cable Coating

- Fire Cable

- Public Address Systems

- Hydraulic Hose

- Fire Suppression Systems

- Contact Us

Direct Tube Based Fire Suppression System

25000 INR/Piece

Product Details:

- Weight KG Kilograms (kg)

- Color RED

- Input Power WATT Watt (W)

- Alarm YES

- Usage INDUSTRY

- Frequency HZ Hertz (HZ)

- Material M.S

- Click to view more

X

Direct Tube Based Fire Suppression System Price and Quantity

- 1 Piece

- 25000 INR/Piece

Direct Tube Based Fire Suppression System Specification

- INDUSTRY

- HZ Hertz (HZ)

- 1 YEARS

- M.S

- WATT Watt (W)

- CELSIUS Celsius (oC)

- INDUSTRY

- YES

- RED

- KG Kilograms (kg)

- METER Meter (m)

- FIRE SUPPRESSION SYSTEM

Direct Tube Based Fire Suppression System Trade Information

- Cheque

- 100 Piece Per Month

- 7 Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

- LOT

- Asia

- All India

- ISO & CE CERTIFICATE

Product Description

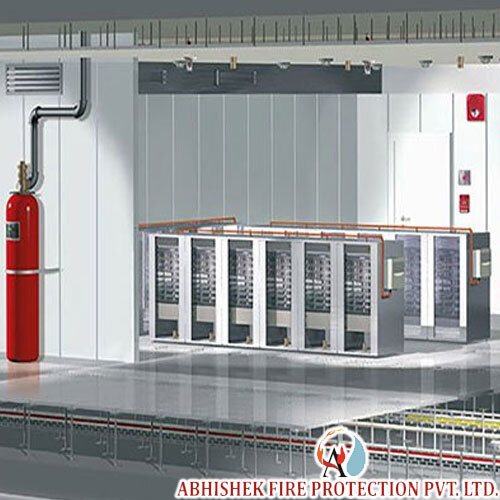

A Direct Tube Based Fire Suppression System, often referred to as a "fire suppression tube" or "automatic fire suppression tube," is a type of fire protection system designed to quickly and effectively extinguish fires in enclosed spaces. It consists of a flexible tube filled with a fire suppressant agent and is typically installed near potential fire hazards or within equipment that may be prone to fire outbreaks.

Heres how a direct tube-based fire suppression system typically works:

1. Tube Installation: The flexible tube is installed in the area or equipment where fire protection is needed. It can be configured to fit various shapes and sizes, making it versatile for different applications.

2. Detection: The system may include a heat-sensitive element or a detection device that monitors temperature or detects flames. When a fire is detected, the system activates the next steps.

3. Activation: When the system detects a fire or excessive heat, it triggers the activation mechanism. This can involve rupturing the tube or releasing a gas or liquid fire suppressant agent.

4. Fire Suppression: The fire suppression agent inside the tube is released directly onto the fire source. This agent can be a variety of materials, including clean agents like HFC-227ea or Novec 1230, dry chemicals, or even water mist, depending on the application and the fire risk.

5. Extinguishing the Fire: Once the fire suppressant agent is released, it quickly suppresses the fire by removing heat or interrupting the chemical reaction that sustains the fire. The speed at which it acts can help prevent the fire from spreading further.

Key advantages of direct tube-based fire suppression systems include:

1. Rapid Response: These systems can detect and suppress fires quickly, minimizing damage and potentially saving lives.

2. Compact and Versatile: The flexible tube can be installed in tight spaces and customized to fit various applications.

3. Minimal Maintenance: They often require less maintenance compared to traditional sprinkler systems.

4. Clean Agents: Some systems use clean agents that leave no residue and are safe for sensitive equipment.

5. Cost-Effective: They can be cost-effective solutions for specific fire hazards.

Common applications for direct tube-based fire suppression systems include electrical cabinets, server rooms, industrial equipment, vehicles (e.g., engine compartments), and other enclosed spaces where traditional fire protection methods may not be practical.

Its essential to design and install these systems in accordance with local fire codes and regulations and to have them regularly inspected and maintained to ensure their effectiveness in case of a fire emergency. Additionally, the choice of fire suppressant agent should align with the specific fire risks and environmental considerations of the protected area.

FAQs of Direct Tube Based Fire Suppression System:

Q: What is the material of the Direct Tube Based Fire Suppression System?

A: The material of the Direct Tube Based Fire Suppression System is M.S (Mild Steel).Q: What is the input power requirement for the Direct Tube Based Fire Suppression System?

A: The input power requirement for the Direct Tube Based Fire Suppression System is WATT Watt (W).Q: What is the weight of the Direct Tube Based Fire Suppression System?

A: The weight of the Direct Tube Based Fire Suppression System is KG Kilograms (kg).Q: What is the color of the Direct Tube Based Fire Suppression System?

A: The color of the Direct Tube Based Fire Suppression System is RED.Q: What is the temperature range that the Direct Tube Based Fire Suppression System can operate in?

A: The temperature range that the Direct Tube Based Fire Suppression System can operate in is CELSIUS Celsius (oC).Q: What is the frequency of the Direct Tube Based Fire Suppression System?

A: The frequency of the Direct Tube Based Fire Suppression System is HZ Hertz (HZ).Q: What is the warranty period for the Direct Tube Based Fire Suppression System?

A: The warranty period for the Direct Tube Based Fire Suppression System is 1 year.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Fire Suppression Systems' category

" We mainly want inquiries from Gujarat, Rajasthan, Madhya Pradesh, Maharashtra, Goa. "

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese